Introduction

PVC/CPVC Molding Guide

PVC and CPVC Materials, Scientific Processing, Troubleshooting, Drying, Purging, and Other Practical Information — authored by Daniel Stephens

Plastics is a sophisticated and diverse discipline. To excel, you need a good grasp of a wide range of concepts and data. The purpose of this guide is to provide PVC/CPVC processors with information that can help them to process, document, and troubleshoot more effectively.

While Routsis Training hopes you find this information useful, it should not be considered a substitute for continuous education. Techniques and technologies are advancing rapidly throughout the industry, which is why top-performing professionals turn to companies such as Routsis Training to keep enhancing their knowledge and skills.

We invite you to further explore the topics covered in this guide through the comprehensive array of online training programs we provide at www.traininteractive.com.

Disclaimer

This reference guide contains general recommendations intended solely for informational use within the PVC & CPVC molding industry. It is not intended to serve as engineering advice.

The information contained herein is based on published information, knowledge, research, and experience which are presumed to be accurate and complete to the best of our ability.

All information is based on averaged data of commonly available grades of plastics and current industry practices at the time of this printing. Therefore, it is the user’s responsibility to review and confirm all design, calculations, and processing decisions.

You should always design and process using the recommendations that are provided by your raw material supplier, resin distributer, machine and equipment supplier(s).

Each material, machine, and process have their own set of influencing factors and, therefore, may or may not comply with the information provided in this guide. Routsis Training, LLC will not accept responsibility or liability for use of the information contained within this guide.

Contact Us

Routsis Training, LLC

379 Amherst Street PMB 233

Nashua, NH 03063 (USA)

phone:(978) 957-0700

website:www.traininteractive.com

store:store.traininteractive.com

email: info@traininteractive.com

PVC & CPVC Polymers

Definition of PVC

Polymers are large molecular chains made up of many smaller molecules. The word polymer can be broken up into two parts:

- Poly means “Many”

- Mer means ”Unit”

- Polymer means “Many Units”

A polymer consists of many smaller molecules called monomers. These monomers are combined into longer polymer chains. The process used to combine these molecules is called polymerization. In most cases, the longer the polymer chains, the tougher and stronger the polymer.

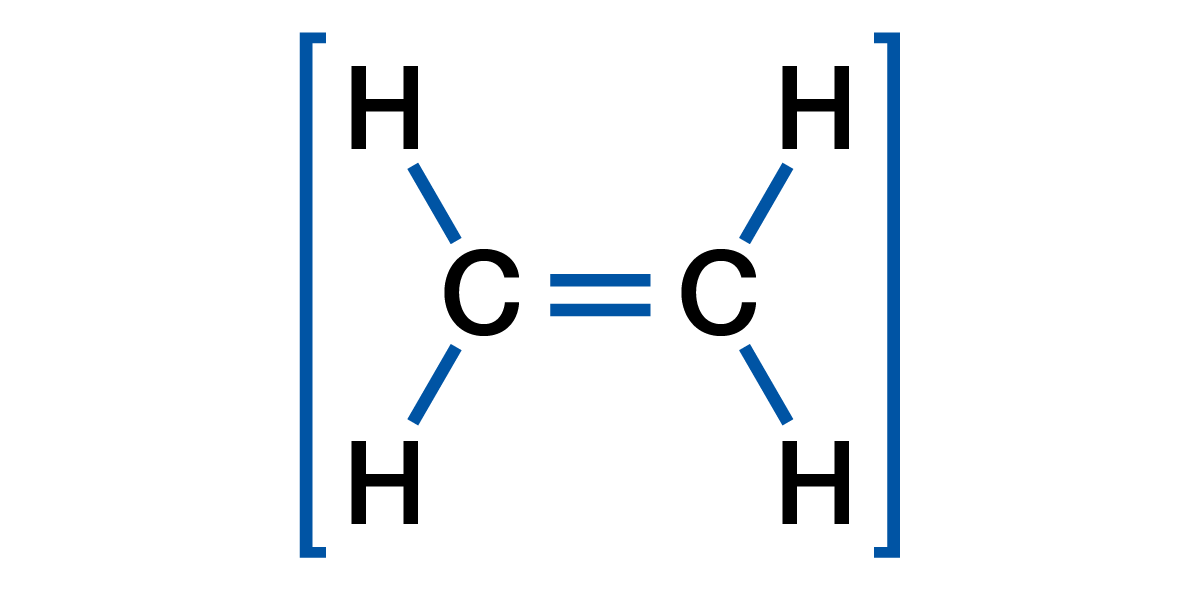

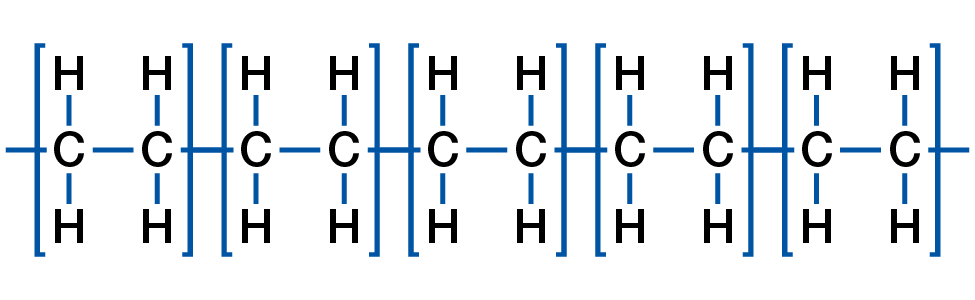

Polyethylene, for example, is one of the most commonly used polymers in the world. This polymer starts with an ethylene monomer of 2 carbons and 4 hydrogen atoms: When polymerized, Polyethylene is comprised of hundreds, thousands, or millions of repeating Ethylene units.

Smaller polyethylene chains (consisting of only hundreds of repeating units each) are often used for low strength applications, such as candle wax. Longer polymer chains make stronger polyethylene, which can be used for injection molding, extrusion, and blow molding processes.

Polyethylene, like all polymers, gets much of its strength from the entanglement of all these relatively long polymer chains. This strength is the highest when the polymer is cooled and the atoms are in a ‘low energy’ state where they are difficult to move around and untangle.

Ethylene Monomer

Polyethylene Polymer

PVC Polymer

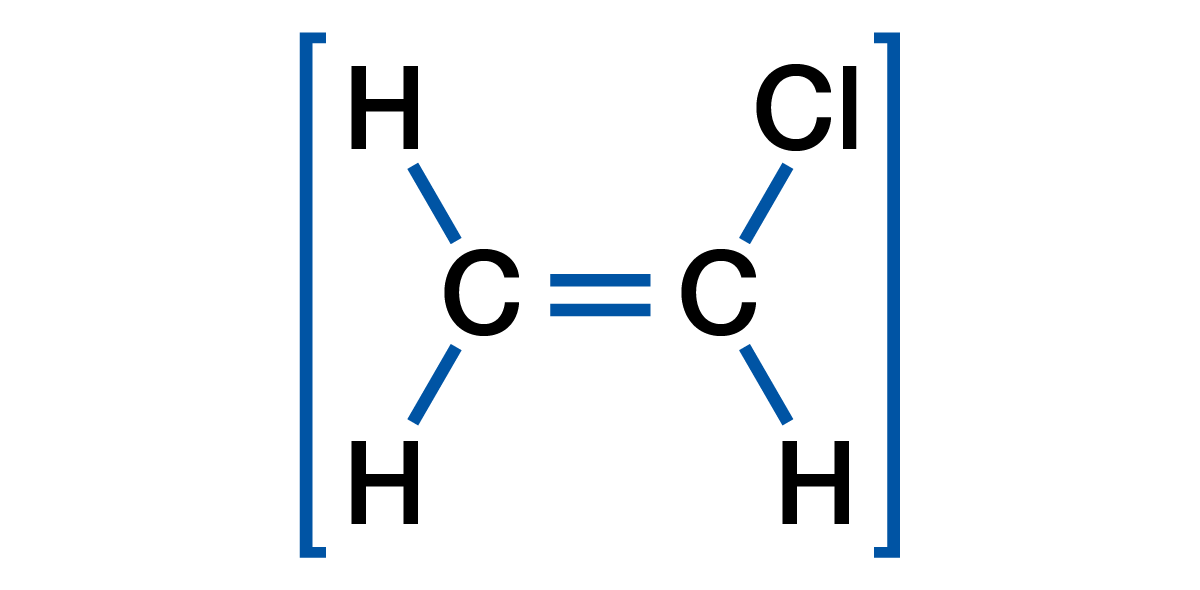

The Polyvinyl Chloride, or PVC, polymer starts with a monomer known as Vinyl Chloride. Vinyl Chloride is comprised of 2 Carbon, 3 Hydrogen, and 1 Chlorine atom.

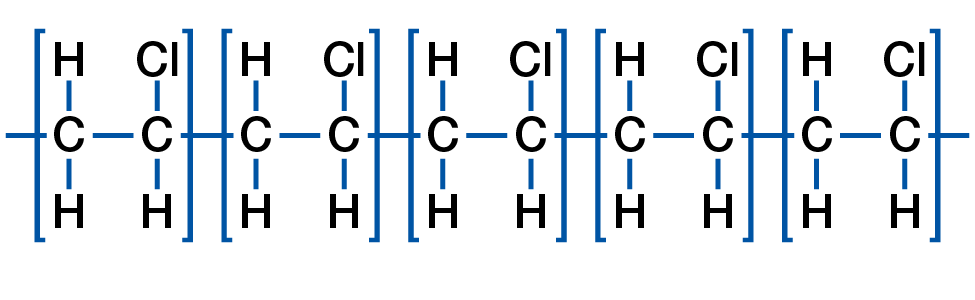

When polymerized, the Vinyl Chloride monomer becomes the Polyvinyl Chloride polymer which is commonly known as PVC.

Vinyl Chloride Monomer

Polyvinyl Chloride Polymer

PVC gets very rigid when it cools, thus when these stiff PVC chains entangle, they gain a lot of strength. This chain entanglement contributes to much of PVC’s overall strength. The atoms on one polymer chain are also attracted to atoms on adjacent chains resulting in significant intermolecular attraction. The combination of rigid chains and intermolecular attraction cause the PVC polymer to be very hard and rigid. This rigidity makes PVC very difficult to process as the polymer chains will break if subjected to too much work and shear when melting or processing. Viscosity is a material’s resistance to flow, the higher the resistance to flow, the higher the viscosity. The rigidity of PVC causes the polymer to have a very high viscosity as compared to many other polymers.

The chlorine present on every unit of the PVC polymer chain causes material be less heat stable than most polymers during processing. When melt processing PVC, it is always important to avoid processing the material with too much heat or shear. When PVC degrades, one byproduct is chlorine gas, which is very dangerous and corrosive when not properly ventilated. The byproduct of degraded PVC will cause any PVC it comes in contact with to start degrading immediately. If excessive PVC degradation occurs, the result could be a cloud of chlorine gas or an explosion, both of which are very dangerous and potentially deadly. These gasses also contribute to the corrosion of metal surfaces such as the screw, barrel, die, and any exposed metal around the processing equipment.

When processed, PVC gives off a highly corrosive chlorine gas. This chlorine gas will accelerate rust, corrosion or oxidation on any surface it encounters including stainless steel. It is imperative that all exposed machinery and die surfaces are routinely cleaned, lubricated, or protected to prevent premature corrosion. There are also chlorine neutralizing sprays which can be used on the mold or die surfaces after processing PVC to reduce post-processing corrosion.

Chlorine and CPVC

PVC has good fire resistance, but the addition of chlorine to the PVC polymer chain will further increase the heat and fire resistance of the end product. Additional chlorine can be added through chlorination making a more rigid material known as Chlorinated Poly-Vinyl Chloride or CPVC. The extra chlorine increases chain rigidity and intermolecular attraction making the polymer very strong, rigid, and more difficult to process.

CPVC is challenging to process because it is much more rigid than PVC — with a much higher viscosity. CPVC is so rigid that it can be difficult to process without causing material degradation. For most of the remainder of this guide, PVC and CPVC will be used together as the concerns when processing the two materials are similar even though CPVC is more difficult to process.

Crosslinking of PVC or CPVC

The Vinyl Chloride monomer is turned into the PVC and CPVC polymer during polymerization. Most grades of PVC/CPVC will polymerize into long chain thermoplastic polymers.

Under the right conditions such as when degrading or when exposed to radiation, PVC and CPVC will cross-link. Crosslinked polymers are called thermoset polymers. These thermoset PVC/CPVC polymers are less common because they cannot be reground and re-processed. The remainder of this guide only focuses on the processing of Thermoplastic PVC/CPVC polymers and does not cover thermosets.

PVC & CPVC Components and Additives

Any additive, plasticizer, colorant, and heat stabilizer must be properly combined into a homogenous mix with the PVC or CPVC during processing or the material will not reach peak performance.

Fillers & Additives

Many different fillers and additives such as Talc, Calcium Carbonate, Sodium Sulfate, Glass Fibers, and colorants can be added for many reasons. Additives and fillers are introduced early in the polymer blending process. These could be added to reduce the cost of the material, increase the strength of the material, change the color, adjust the gloss, or even increase the density of the material.

Plasticizers

Due to the rigidity of PVC and CPVC, plasticizers are added during blending to help the polymer flow when processed. Large amounts of plasticizers are added when flexible PVC polymers are being blended. Plasticizers are usually comprised of smaller molecules which reduce the intermolecular entanglement or molecular attraction.

Rigid PVC and CPVC have a high viscosity because they use a minimal percentage of plasticizers to help flow, yet allow the final product to retain its stiffness. Rigid PVC and CPVC are commonly used for high strength applications such as plumbing pipes, pipe fittings, house siding, window frames, and control panels on ‘white goods’ such washing machines and dish washers.

Flexible PVC uses a much higher percentage of plasticizer to reduce the stiffness of the intended products. A further benefit of using a plasticizer is that it reduces the viscosity of the PVC. Common uses for flexible PVC are tubing, synthetic leather, shower curtains, films, and gaskets.

Heat Stabilizers

PVC and CPVC degrade very easily. Heat stabilizers are added during polymer blending to help reduce degradation and improve thermal stability when processing. The most common heat stabilizers are metal-based and often include multiple elements such as tin, barium, and calcium. These additives can withstand heat much better than PVC or CPVC alone, which improves thermal stability during processing.

PVC & CPVC Regrind

Thermoplastic polymers can be reground and re-processed, but PVC and CPVC can only be reprocessed until they degrade. When PVC or CPVC degrades, the degraded material will cause any PVC or CPVC molecules it encounters to degrade quickly due to a rapid chemical reaction. For this reason, you cannot put degraded PVC or CPVC back into the process or it will rapidly create more degraded PVC in the barrel and in your final product.

Since PVC and CPVC degrade easily, you must always be careful when processing regrind. Good quality PVC and CPVC regrind may have value as can be reprocessed. Good quality regrind refers to reground material which has no contamination or degradation.

Bad quality PVC or CPVC regrind has a negative value and will not only create more scrap in your process, but will also lead to more degraded PVC or CPVC. It is more cost effective to discard bad PVC or CPVC as processing degraded regrind material will lead to increased scrap and production losses. If your PVC or CPVC has degraded regrind in the mix, then it will create more degraded PVC in your final product. Degraded regrind or contamination will create a lower quality part which will likely have reduced properties such as poor strength, impact resistance, chemical resistance, and appearance. Processing degraded regrind will increase the chances that faulty product will reach your customers.

Performance vs. Non-Performance PVC & CPVC

Processing Performance PVC or CPVC

Performance PVC and performance CPVC refers to plastic used for functional applications such as pipes, fittings, siding, films, hoses, tubing, bottles, and window profiles. These products must meet specific performance requirements such as tensile, flexural, compressive, impact strength, and/or resistance to chemicals, UV, or radiation. The PVC or CPVC reaches peak performance when all the additives, plasticizers, heat stabilizers, etc. are thoroughly mixed which is a condition known as gelation or fusion.

Without proper gelation or fusion, the performance products may fail during use. It is common for performance products to meet all visual and dimensional requirements but fail when put through performance testing. This is often the result of inadequate gelation in the final product. Gelation and fusion will be covered in later sections of this guide, but general discussions related to Performance PVC/CPVC is covered below.

Performance polymers should be close to peak gelation or fusion at the end of the process to achieve the highest possible performance. When polymers reach peak gelation or fusion, the PVC or CPVC cannot accept much more time, temperature, or shear before the polymer begins to start degrading. For this reason, it is very difficult to process regrind made from performance PVCs. Regrind performance PVC or CPVC degrades easier than the virgin material in the pellet or powder forms because it has an additional time, temperature, and shear history. When regrind is incorporated in performance PVC and performance CPVC applications, the percentage used is often below 10% to prevent potential degraded material from causing significant performance losses. Waste material which does not show any signs of degradation such as burning, streaks, dieseling, or die lines is considered as usable regrind.

Documenting Performance PVC or CPVC

Essentially, the correct balance of time, temperature, and shear will help the PVC or CPVC fully mix and approach peak gelation or fusion. When the process makes acceptable product which meets all the visual and performance requirements, is it critical to fully document the process. This process documentation should include all the factors which go into making a good product. Specifics will be covered in later sections of this guide, but general documentation guidelines are covered below.

Machine, auxiliary, and downstream information should be recorded with any critical process information. Detailed process output data should be recorded as well as any information which helps identify what made good product during the specific production run. This includes the material lot, blending facility and equipment, pelletizing facility and line, percentage regrind, and any rheological information such as melt flow index, dryer residence time, barrel residence time, material temperature, coolant temperature, and any results from post-production testing including dimensional and gelation-related data.

Detailed process documentation should identify the factors which specifically relate to gelation or fusion such as all time, temperature, and shear factors. This way, the processor has information to help make process adjustments to compensate for time, temperature, and shear factors differences between one production run and another.

Proactive Process Adjustments

For performance PVC or CPVC applications, good process documentation allows the processor to make predictive adjustments based on an expected change in the time, temperature, and/or shear in an upcoming run. For example, if an upcoming production run is going to contain regrind, the barrel temperatures can be reduced to help mitigate the additional heat the regrind adds to the process. If a production run is scheduled to be run in a machine with a smaller barrel, the barrel temperatures or pressures might need to be increased to put more temperature or shear into the material – this can help compensate for the shorter time the PVC or CPVC will spend in the smaller barrel.

When using different equipment or material from run to run, a modified process may be necessary to get the same product performance. As a processor, you can control aspects of time, temperature, and shear on the PVC or CPVC, but many times it is the role of the processor to compensate for changes they cannot control such as a different machine or lot of material. The more a processor can predict these changes, the less scrap will be produced and the higher the production efficiency your process will have.

A proactive approach is important for performance PVC and CPVC applications. This is because most performance testing requires a specified time to pass such as 12 or 24 hours before the product can be properly tested. If a processor can gain some skill and experience in making effective proactive process adjustments, then it is often possible to run production while the product waits to be tested because there is a high-level of confidence that the product being produced will meet all quality parameters including performance testing.

Reactive Process Adjustments

The first use of this data is to make process adjustments on setting up, followed by adjustments after the product is found to be defective. If the PVC or CPVC shows degradation, then there needs to be a reduction in time, temperature, and/or shear such as a reduction in screw speed, barrel temperature, or a change to a machine with a smaller barrel. Conversely, if there is not enough gelation, then the time, temperature and/or shear applied to the material will need to be increased to get more gelation.

When using the same or similar processing equipment, the same process should be used to maintain the same balance of time, temperature, and shear. The part is likely to perform the same in testing, but good documentation will help you determine and compensate for differences during startup.

Keep in mind that many flexible PVC or CPVC applications can be considered performance PVC or performance CPVC applications if they must meet specific performance requirements such as chemical resistance or chemical characterization testing which require the PVC to be at near peak gelation or fusion to pass.

Non-Performance PVC Products

“Non-Performance” refers to non-functional applications such as decorative parts like panels, trim, and appliance panels. These products tend to have specific visual and fit requirements, but the PVC or CPVC does not have to perform at or near its peak strength or resistance capabilities.

These parts should always be processed with the minimal time, temperature, and shear necessary to make good product. This strategy provides the processor with a larger process window with the least likelihood of degrading the polymer. If the PVC or CPVC is processed at conditions significantly lower than necessary to achieve peak gelation, the defective products and waste can be reground and reprocessed with a lower risk of degradation.

As with Performance PVC and Performance CPVC applications, it is important to document all factors that make acceptable product, including all process outputs, material data, and time, temperature, and shear information. The positive aspect to non-performance PVC and non-performance CPVC is that you can usually match up the process outputs on similar processing equipment and the process should make good product. The detailed process documentation will help you identify and make efficient reactive adjustments when a significant change occurs in the time, temperature, and shear relationship such as degradation.

When using significantly different material grades and batches, or changing machinery from run to run, a proactive process adjustment should be considered before the process is started. This is recommended for non-performance PVC/CPVC applications to increase the efficiency of a production run. However, it is not typically as critical as it tends to be with performance PVC/CPVC products.

Time/Temperature/Shear Relationship for PVC & CPVC

Performance vs. Non-Performance

Performance PVC and performance CPVC refers to polymers which must meet stringent strength or resistance properties. For the purpose of this guide, we will occasionally differentiate these polymers from non-performance PVC or non-performance CPVC polymers where the application may have specific appearance or dimensional requirements but does not have stringent performance requirements.

Gelation (Fusion) Concerns

Once the polymer, additives, plasticizers, heat stabilizers, and other components in PVC or CPVC are fully mixed, the polymer is at peak strength. This is known as gelation (or fusion) because all of the components have become combined or fused into what is known as a gel. Full gelation refers to the point where the polymer matrix has fully formed, and it has achieved its optimal strength.

It is important to note that performance PVC and performance CPVC plastics are provided to the processor in a blended form, but all the components are not fully mixed when in pellet or powder form. This is because the process to properly combine all these elements puts excess heat and shear into the polymer. If this is all done before final processing, then the polymer will start to degrade once it is re-melted to processing temperatures. It is the job of the processor to complete the combining of the Rigid PVC or CPVC with the desired additives in the barrel. When done properly, the plastic in the final product has adequate gelation to achieve the desired properties.

Rigid PVC or CPVC products which have not reached full gelation will have reduced physical properties such as low impact, flexural, tensile, or compressive strength. These polymers which have low-strength will also have reduced resistance to attack from chemicals, UV rays, and electricity. Low gelation can cause product failures in the field such as bursting pipes, breaking fittings, cracked siding, leaking containers, or even food contamination.

The biggest problem the performance PVC/CPVC processor faces is when the material has not reached high gelation. In this instance, the plastic product may look good and meet the dimensional requirements and preliminary quality checks, but fail when the final product is tested for performance such as a pressure, strength, crush, flexural, impact, or chemical testing.

For performance PVC or CPVC to reach high gelation, a proper combination of time, temperature, and shear must be applied to the polymer. Gelation will not occur if there is too little time, temperature, or shear involved in processing. Unfortunately, when too much time, temperature, or shear is applied to the PVC or CPVC, it will begin to degrade. Good PVC and CPVC processing is based on understanding the proper balancing of time, temperature, and shear for your specific application.

In the Process Documentation portion of this guide, we’ll review how to document time, temperature, and shear on your process documentation.

Time

With respect to time, temperature, and shear for performance PVC or CPVC, time refers to the time the PVC or CPVC is exposed to heat and/or shear. To effectively combine all the polymer components and additives, both heat and shear must be applied over a period of time. Time examples include:

- Barrel Residence Time

How long the polymer remains in the barrel exposed to heat - Cycle Time

The time required to produce a fixed amount of product - Dryer Residence Time

How long the polymer remains in the dryer exposed to heat - Blending Time

How long the polymer is exposed to heat and shear during component blending

If any PVC or CPVC is exposed to heat or shear for an excessive amount of time, the polymer will begin to degrade. If performance PVC or CPVC is not exposed to heat or shear for enough time, insufficient gelation will occur, and the resulting product will not meet the end use requirements.

This time factor is very important to consider during production stoppages, slowdowns, shutdowns, startups, and changeovers as the polymer will begin to degrade. This is why it is very important to replace all the PVC with heat stable polymers immediately whenever the processing equipment is to be down or idle for any extended period of time.

Temperature

Temperature refers to the heat history applied to the PVC or CPVC. To effectively combine all the components, heat is a necessary factor. Without applying heat, the PVC and CPVC polymer chains would be too rigid to properly mix. Temperature examples include:

- Blender Temperature

- Barrel Zone Temperatures

- Die or Hot Runner Temperatures

- Dryer Temperatures

- Coolant Temperatures

Temperature control is critical with PVC or CPVC. A temperature spike occurring anywhere during mixing, pelletization, drying, or processing can start the degradation process. To reduce heat generation, PVC or CPVC molding machines and extruders should use barrel heaters equipped with cooling fans. These fans circulate air around each barrel zone to prevent the material from overheating. In many instances, cored extruder screws cooled by air or oil mail may be used to help prevent overheating of the polymer during processing.

Shear

Shear refers to the work or mechanical energy applied to the PVC or CPVC. To effectively combine all the components, shear is a necessary factor as the polymer must be thoroughly mixed. Examples of when PVC or CPVC is sheared include:

- Material mixing and blending

- Pelletization

- Screw rotation and screw geometry, features and characteristics

- Back pressure or die head pressure

- Material flow through the die or mold

- Restrictions or blockages in the die or mold

With PVC or CPVC, shear creates significant heat. Always be very careful whenever adding shear to a PVC or CPVC process. Adding both energy and heat can bring the material to the point of degradation very quickly.

Gelation (Fusion)

The point where PVC or CPVC approaches peak mixing of components is called gelation (or fusion). When gelation occurs, the PVC or CPVC polymer has the highest strength, impact resistance, chemical resistance, heat resistance, fire resistance, and UV resistance. Gelation is critical for high performance PVC or CPVC products such as pipes, fittings, containers, siding, window casings, and medical tubing.

Incomplete or non-gelation: Many parts look good after processing but have not reached gelation resulting in lower mechanical and resistance properties. In most cases where performance is critical, insufficient gelation will often result in parts failing during use.

Non-gelation is generally acceptable for applications such as appliance panels, decorative components, and other low-risk applications where fit and appearance is more important than performance.

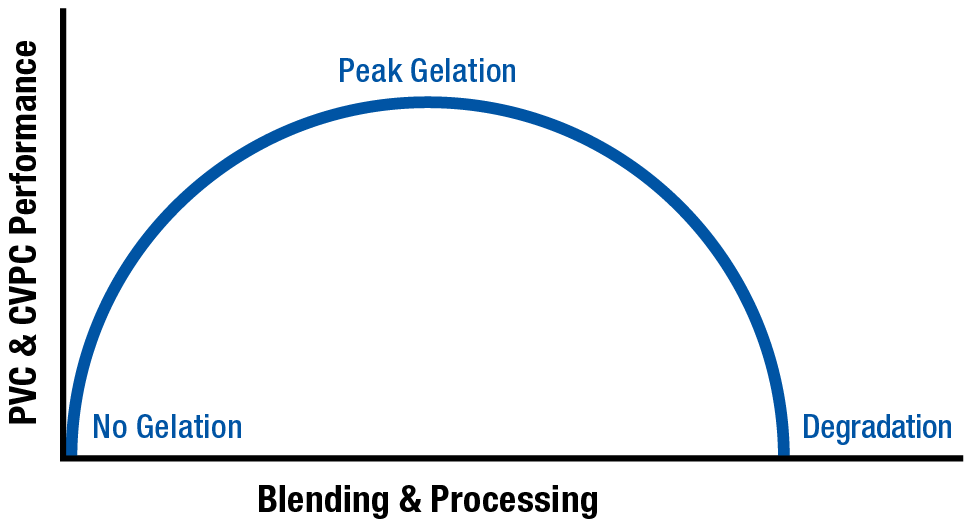

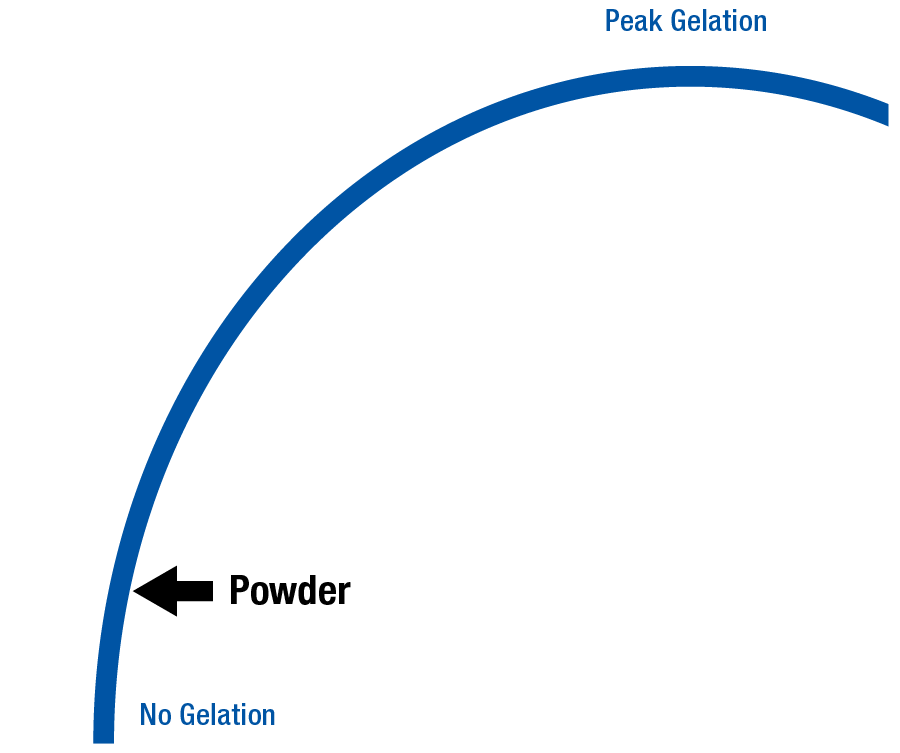

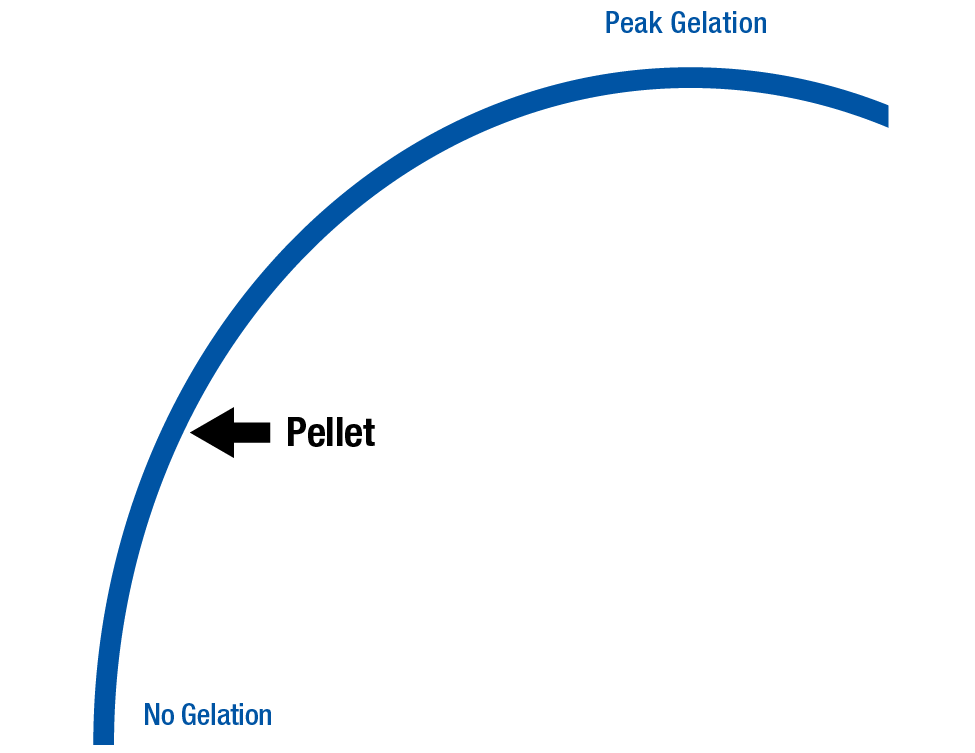

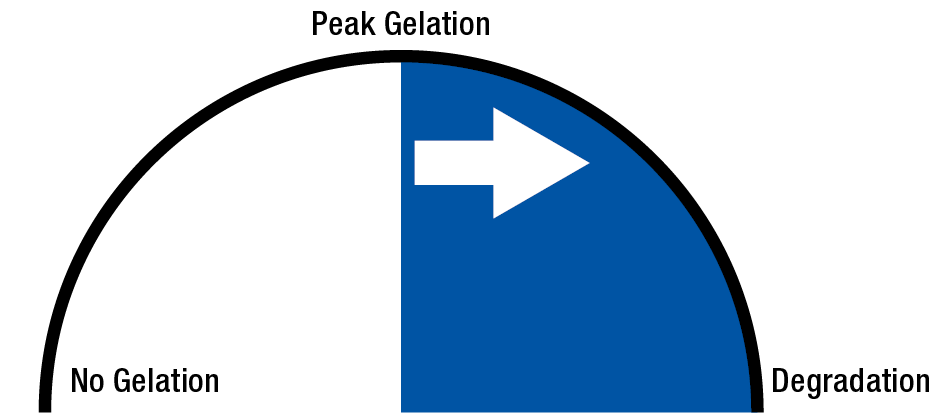

The figure below shows the starting state of polymer with the lowest strength at ‘No Gelation’. Once the polymer starts receiving a time, temperature, and shear history the strength of the polymer increases with corresponding increase in gelation. Once too much time, temperature, or shear is applied, the PVC or CPVC will start to degrade resulting in a loss in polymer properties the more it degrades.

PVC/CPVC Gelation Arc

PVC Degradation

Once a high level of gelation or fusion is achieved, additional time, temperature, or shear will begin the degradation process. Once PVC or CPVC begins to degrade, it undergoes a chain reaction which accelerates more degradation of adjacent PVC chains.

This degradation chain reaction is a primary reason why it’s critical that all PVC or CPVC processing equipment is streamlined: without any gaps or hang-up points where the polymer flow can stop. If the PVC or CPVC stagnates at any point, the stagnated polymer will degrade — in turn, causing all polymer that touches it to degrade.

This degradation is often seen in extrusion in situations where degraded PVC/CPVC is present inside or on the edge the extrusion die. This will cause a continuous brown stripe in the extrudate until the degraded material is removed from the die. Another example of this is degraded material in the nozzle of an injection molding machine. This degraded PVC or CPVC will cause brown streaks on the gate area of the molded parts on every cycle until the process is stopped and the nozzle is properly cleared of degraded material.

Excessive PVC degradation is very dangerous. As mentioned before, polymer chains degrade in a rapid, continuous reaction. Toxic chlorine gas can be produced rapidly and the polymer chains can crosslink and seize the screw inside the barrel. PVC or CPVC cannot be left in the barrel for any extended period of time. Rather, it must be replaced with a heat stable material, such as a Polyolefin (PE or PP) or Purging Compound.

Testing of Gelation or Fusion of PVC & CPVC

The only way to know the amount of gelation or fusion in your PVC or CPVC after being processed is to conduct a test on the material using one of the following tests. All the tests in this section apply to testing of the final product. In all cases, the final product testing is destructive, thus you will not be able to sell the product after gelation or fusion is tested.

Chemical Immersion Test

In this test, the PVC is immersed in a chemical for a pre-determined amount of time to visually evaluate the amount of damage the chemical does to the polymer. To conduct this test, the PVC or CPVC sample is cut at an angle to help expose a large amount of internal surface area to the chemical. The internal surface of the PVC must be exposed for this test to provide accurate results because the outer surfaces tend to develop a skin which may resist chemical attack.

For example, ASTM D2152-17 entitled ‘Standard Test Method for Adequacy of Fusion of Extruded Poly (Vinyl Chloride) (PVC) Pipe and Molded Fittings by Acetone Immersion’ uses product which is cut and submersed in acetone for a specified period of time.

If the processed PVC or CPVC have a high amount of gelation or fusion, the PVC or CPVC will show no signs of attack at the end of this chemical immersion test. This means the product has passed the test and is likely to have good strength and resistance properties due to a high degree of gelation or fusion.

If the PVC or CPVC sample shows discoloration, pitting, streaking, or any noticeable change in appearance, the polymer components have not been properly mixed, or some degradation has begun to occur. In either case, the polymer matrix does not have enough gelation or fusion.

The chemical immersion test is a common general test for gelation or fusion because poorly gelated PVC or CPVC will be easily attacked. This is because all the components have not been blended into a cohesive polymer matrix.

The challenge with this test is that the person evaluating the results must have the necessary experience to evaluate minor attacks on the PVC or CPVC. The results of this test are generally considered pass or fail, but an experienced technician can provide a subjective evaluation on the degree of attack and type of damage which has been done to the sample by the chemical.

Aside from Pass or Fail, the results of this test are not quantitative, but observational data can be helpful to the technician – for example, pitting in the tested sample might indicate poor mixing while streaking in the sample may indicate degraded polymer.

The general methodology of the chemical immersion test is straightforward:

- The test sample is prepared by cutting it with an angle to expose the internal polymer

- The area of the sample being tested is submerged into the chemical for a period of time

- The sample is removed and chemical is washed off to make the sample safe to handle

- The exposed polymer is visually inspected to determine whether the polymer passed or failed

Advantages & Disadvantages

There are several advantages and disadvantages associated with using the Chemical Immersion Test to evaluate the gelation or fusion of PVC and CPVC materials.

Advantages:

- Many chemicals are available for use in this test

- Testing is easy to perform

- Cost is low

Disadvantages:

- The test takes a significant amount of time to complete

- The chemicals used can be very dangerous

- Proper PPE and ventilation are required

- Evaluation requires training and experience

- Evaluation of results are very subjective

- Test results are not quantitative

Impact Strength Test

In this test, the PVC or CPVC is subjected to a high-speed impact of a specific weight moving at a specific speed which is measured as energy. In some tests, the sample breaks and the loss of energy is measured. In other tests, the sample is tested at a specific energy level to determine if it will break or not. This is a pass/fail test. With respect to PVC or CPVC, the better the part performs in testing, the more gelation is likely present in the product.

Pendulum Impact Strength Test

The most common form of impact strength test is the pendulum test. In this test, a weighted pendulum is swung through the test sample to break it. The pendulum starts on one side of the testing apparatus from a fixed point and the highest position of the pendulum’s upswing is measured. This measurement corresponds to the amount of energy lost as the pendulum passed through the sample. The less the pendulum swings afterward, the more energy has been lost during the breaking of the sample. In theory, properly gelated product will have a higher energy loss when being tested than low gelation product does.

Different tests may use different weights and methods for holding the sample. For example, ASTM D2560-10 titled ‘Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics’ uses a notched sample which is struck while clamped in a vertical orientation.

The general methodology of different pendulum impact testers is common:

- The test sample is prepared by cutting it to size and often is notched to reduce the effects of the outer polymer skin from skewing the test results

- The sample is secured in the testing apparatus

- The swinging weight is lifted and released from a fixed point

- The energy loss is measured

Falling Weight Impact Strength Test

The falling weight impact test is a simple way to test the impact resistance of a product. These tests use a weight with a piercing element which is dropped from a specific height. The test is designed to determine whether the product resists puncture in a pass or fail evaluation. The energy used in the test is created by the dropping of the weight in the test. In most cases, the product has a specific weight and height impact that it is designed to resist. When the test is designed properly, a well-produced and gelated PVC or CPVC product will pass this test by resisting puncture, while poorly manufactured product will fail the test. Different tests use different weights and points for puncturing the sample. In many applications, the final product is fixtured under the falling weight. This tests how a product will perform when impacted by something realistic such as a hammer.

Different tests may use different weights and methods for holding the sample. For example, ASTM D5420-21 titled ‘Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimen by Means of a Striker Impacted by a Falling Weight (Gardner Impact)’ offers different product geometries, weights, and heights for standardized testing.

The general methodology of falling weight impact testers is common:

- The test sample is prepared by cutting it to size (where applicable)

- The cut sample or finished device is secured in the testing apparatus

- The falling weight is lifted and released from a fixed height

- The sample either passes or fails the test based on whether the product is punctured

Advantages & Disadvantages

There are several advantages and disadvantages associated with using Impact Strength testing to evaluate the gelation or fusion of PVC and CPVC materials.

Advantages:

- Many testing systems are available

- The tests are relatively easy to perform

- Results are easy to evaluate

- Pendulum impact testing is quantitative

- Falling weight impact testing is easy to perform final product

Disadvantages:

- Apparatus used can be dangerous

- Poor results are not always caused by poor gelation or fusion

- Falling weight impact testing is not quantitative

- Extensive testing of good and bad product required to determine pass or fail criteria

Mechanical Strength Test

The purpose for using mechanical strength testing for performance PVC and CPVC is that high-performing product has adequate strength as a result of good processing and adequate gelation or fusion. With any mechanical strength testing, the overall strength of the product being tested can be heavily influenced by the process used to manufacture it. This means that a failure in strength testing could be indicative of a bad process and not necessarily inadequate gelation or fusion.

Since a good product is expected to pass strength testing requirements, this testing method is a good measure of overall product quality, which includes adequate gelation of the PVC or CPVC in the final product.

There are many mechanical testing methods used for testing, but the most common are:

- Tensile Strength (ASTM D638)

Tests resistance to being pulled apart - Compressive Strength (ASTM D695)

Tests resistance to being compressed or crushed - Flexural Strength (ASTM D790)

Tests resistance to being bent or flexed - Pressure Strength (ASTM D1785)

Tests resistance to bursting or leaking under pressure

When tested, the sample is subjected to either a steady strain and the stress and/or failure is measured, or the sample is tested at an increasing stress and the strain and/or failure is measured. In many cases, the strength of the final product can be tested with a properly designed testing apparatus – for example, Pipe fittings are often filled with water and tested with increasing pressure until the product fails by leaking or bursting.

The general methodology of strength testing is common such as:

- The test sample is prepared for the testing apparatus

- The sample is secured in the testing apparatus

- The sample is subjected to either an increasing stress or an increasing strain

- The stress or strain at failure is measured.

Advantages & Disadvantages

There are several advantages and disadvantages associated with using Mechanical Strength testing to evaluate the gelation or fusion of PVC and CPVC materials.

Advantages:

- Many testing systems are available

- The tests are relatively easy to perform

- Results are easy to evaluate

- Most strength testing is quantitative

- Strength testing can often be used on the final product

Disadvantages:

- Apparatus used can be very dangerous

- Poor results are not always caused by poor gelation or fusion

- Extensive testing of good and bad product required to determine pass or fail criteria

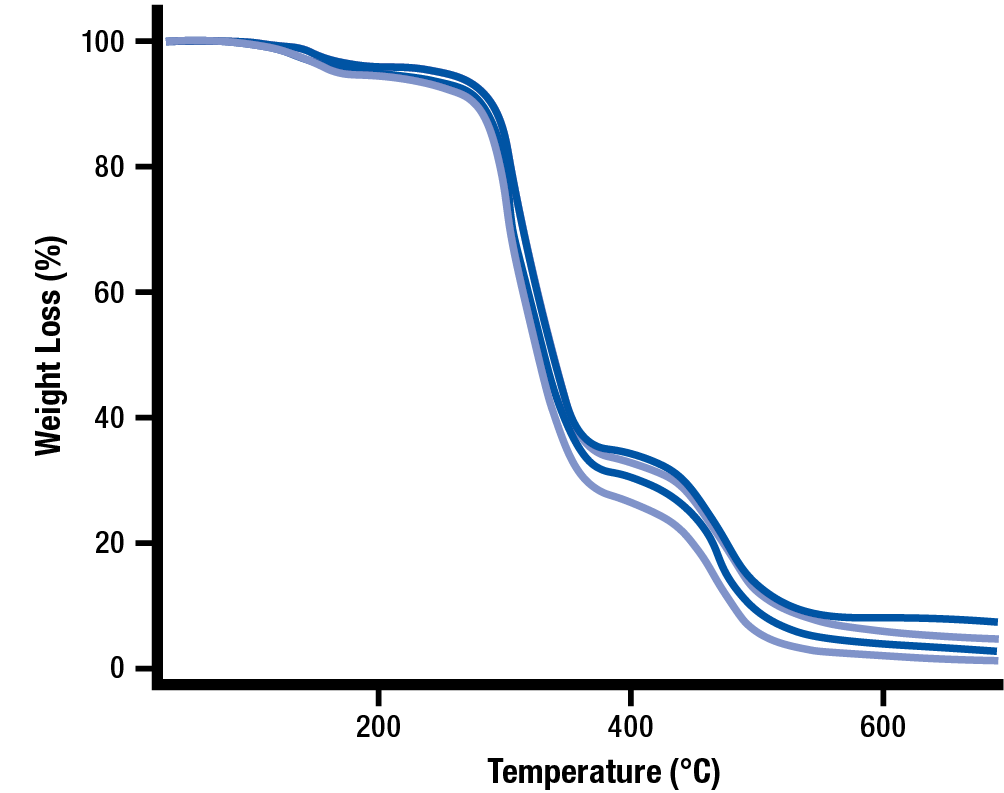

Thermogravimetric Analysis (TGA) Test for Gelation or Fusion

A Gravimetric Analysis test uses a polymer sample placed on a very accurate scale. The sample is subjected to a steadily increasing temperature and the weight loss of the sample is measured. The result of the test is a curve showing the percentage weight loss in the sample on the vertical Y axis and the temperature of the sample on the horizontal X axis. This is known as a gravimetric curve.

Since the test involves heating and burning PVC or CPVC, proper PPE and ventilation is required to conduct this test.

The purpose in using Thermogravimetric Analysis testing for performance PVC and CPVC is that highly-gelated polymer matrix will require a higher temperature to burn off the polymer, resulting in a very specific thermogravimetric curve. This curve would be characteristically different than the thermogravimetric curve of an un-blended or degraded PVC or CPVC polymer.

The person evaluating the test results is responsible for analyzing the gravimetric curve by comparing it to a gravimetric curve of a sample known to have good gelation or fusion. Some systems can determine how much the sample curve differs from the standard, but many thermogravimetric comparisons must be done manually.

The general methodology of Gravimetric Analysis testing is as follows:

- A small test sample is cut from the center of the product

- The scale is zeroed and the sample is placed into the Thermogravimetric Analyzer to be weighed

- The sample is subjected to a heat source which steadily increases the temperature of the sample

- The weight is constantly measured by a computer which generates a gravimetric curve

Sample TGA Graph

Advantages & Disadvantages

There are several advantages and disadvantages associated with using Thermogravimetric Analysis (TGA) to test the gelation or fusion of PVC and CPVC.

Advantages:

- Many low-cost TGA systems are available

- The tests are relatively easy to perform

- The test is evaluating the polymer itself

Disadvantages:

- High-accuracy TGA systems are expensive

- Low-cost TGA systems have poor ventilation

- Evaluation requires training and experience

- Comparative testing of good and bad product is required to determine pass or fail curves

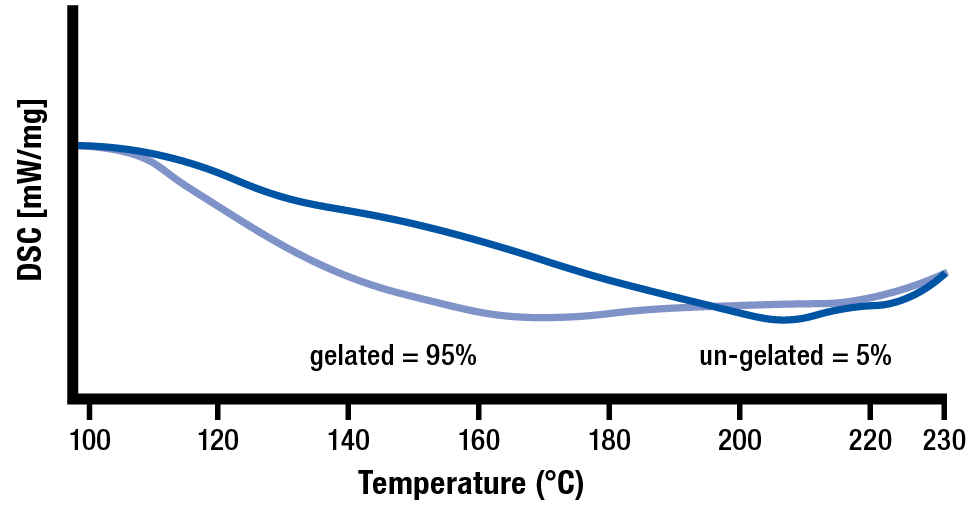

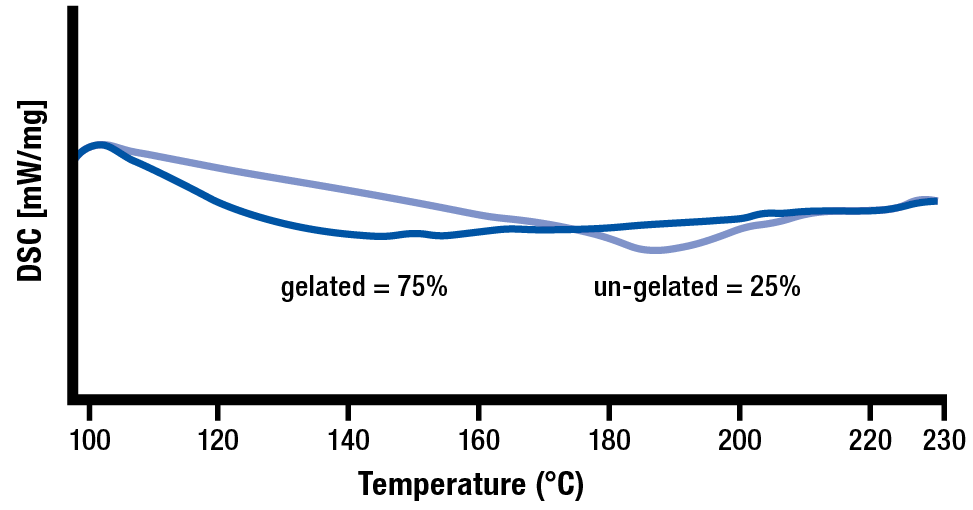

Differential Scanning Calorimetry (DSC) Test

The Differential Scanning Calorimetry (DSC) system heats the polymer sample at a specified rate while the heat flow from the sample is measured. The result of the test is a curve showing the heat flow of the sample on the vertical Y axis and the temperature of the sample on the horizontal X axis.

Since the test involves heating of PVC or CPVC, proper PPE and ventilation is required to conduct this test.

The purpose in using Differential Scanning Calorimetry (DSC) testing for performance PVC and CPVC is that a 100% gelated or fused polymer matrix will heat up as one component because they are fully combined. In contrast, any un-gelated heat stabilizers and fillers will heat up a different rate than the rest of the polymer components. Since it is rare to achieve 100% gelation, the results will have 2 dips in the curve. The area of these curves represent the amount of material which is gelated in the first portion and the amount of un-gelated or unfused material in the second portion.

The DSC software can determine the amount of PVC or CPVC that is in the gelated and un-gelated portion of the DSC curve.

The general methodology of Differential Scanning Calorimetry testing is common:

- A small test sample is cut from the product

- A sample is sealed into a container and an empty comparison container is also sealed

- The samples are placed into the DSC machine and the machine cycle is started

- The sample is subjected to a heat source which heats the sample as well as the comparison containers

- The heat flow for both containers is constantly measured by a computer which generates a heat flux curve and calculated the percentage of gelation or fusion

Example of DSC Curve for 75% Gelation of Fusion

Example of DSC Curve for 95% Gelation of Fusion

Advantages & Disadvantages

There are several advantages and disadvantages associated with using Differential Scanning Calorimetry (DSC) to evaluate the gelation or fusion of PVC and CPVC.

Advantages:

- The test is evaluating the polymer itself

- Percentage gelation is analyzed and provided by the DSC system

Disadvantages:

- DSC systems are expensive

- Sample preparation requires training and experience

PVC & CPVC Powder, Pellets, and Regrind

Powder

Many processors use PVC or CPVC powder, which is commonly compounded in-house using large blenders. This powder is mixed and blended at controlled shear rates and temperatures to help provide a consistent material source with the same amount of time, temperature, and shear history with each batch.

It is best to use the same blending equipment for each lot to prevent variation in the quality of your PVC/CPVC source material. Most material suppliers can provide you with information about the blending equipment used and the location of the facility. Many suppliers will be able to provide you with material from the same facility or line if you work with them.

When powder is melted and processed, most of the gelation takes place in the barrel. The processor has significant control over degree of gelation when the PVC/CPVC is in powder form. Keep in mind, powders from different suppliers will have completely different time, temperature, and shear histories — requiring significantly different processes to obtain similar final part performance.

With powder, the processor controls a high percentage of the gelation (or fusion) during processing.

PVC or CPVC Powder on Gelation or Fusion Arc

Pellets

When PVC or CPVC powder is processed into pellets, the polymer is exposed to another time, temperature, and shear history. Pelletization takes place in an extruder — where the powder is melted, extruded, and cut into pellets. As a result, more progression towards gelation has occurred in the pellets when compared to its original powder form.

It is critical that your pellet supplier uses the same blending equipment and extrusion line to process your PVC/CPVC pellets. A change in equipment or processing conditions significantly changes the amount of gelation present in the pellets you receive. Essentially, PVC and CPVC lots received from different pelletizing lines will have different time, temperature, and shear histories — requiring different amounts of work during processing to reach peak gelation.

PVC/CPVC powders are very sensitive to time, temperature and shear when compounding into pellets. During pelletizing the blending and extrusion equipment are critical to these properties and should not be altered from lot to lot, as changes may affect material properties. All changes in time, temperature, or shear during the pelletization process must be communicated by the material supplier since these changes can alter the final process. When pellets incur more processing time/temperature/shear, they are likely to encounter increased degradation when processed.

With pellets, the processor typically controls half of the gelation process.

PVC or CPVC Pellets on Gelation or Fusion Arc

Regrind

There are many concerns when processing reground PVC and CPVC since the regrind material already has multiple histories of time, temperature, and shear. These concerns include:

- Powder Blending and Mixing

- Polymer Pelletizing

- Material Drying

- Melt Processing

- Grinding into Regrind

All of the above processes involve exposing the polymer to heat and shear. Sometimes this exposure takes place for hours as with material drying. Low RPM grinders are strongly recommended when regrinding PVC and CPVC, as they generate less heat during the grinding process.

Since the PVC/CPVC may have reached peak gelation, the reground material is much closer to degradation than it was in powder or pellet form. PVC or CPVC regrind is very difficult to process without causing degradation; therefore, lower percentages of regrind are always preferred. Frequent testing and inspection should also be used whenever processing with PVC/CPVC regrind to help identify any degradation that might be occurring.

Be cautious when mixing PVC Pellets with PVC Regrind since they both have different time, temperature, and shear histories. The resulting product may be inconsistent and should be closely monitored. For these reasons it is very important to closely monitor your incoming stream of PVC and CPVC regrind. Higher percentages or low-quality PVC/CPVC regrind will limit the amount of gelation possible with the final product.

Burnt or Degraded PVC or CPVC

You should never regrind and reprocess burnt or degraded PVC or CPVC. This material has negative value as it will cause rapid degradation of any PVC or CPVC it contacts. Any burnt or degraded PVC/CPVC material that enters the barrel will begin a chain reaction which can reduce the visual appearance, physical properties, and resistance properties of your final product. This means that a small percentage of degraded PVC/CPVC will prevent the material from reaching peak gelation render the final product useless. This is why the use of regrind must be strictly controlled and monitored in any performance PVC/CPVC applications where high percentages of gelation is required.

Too much burnt or degraded PVC or CPVC entering the barrel creates an extremely dangerous situation, which can result in the release of toxic chlorine gas — and an explosion of the barrel, endcap, or hopper. All of these situations have been known to cause serious injury and death at PVC/CPVC processing facilities.

For this reason, it is recommended to avoid putting any visually burnt or degraded polymer in the regrind stream. Sometimes this involves throwing away the entire piece, but it may involve cutting away the burnt or degraded section and retaining the rest of the piece.

Some companies invest in high-speed particle sorting equipment, such as those used in food applications to separate contaminants. As long as your part is not dark in color, these systems can visually sort out pieces of burnt and degraded regrind from the good regrind. These machines are not perfect, but can be great way to help maintain a better, more reliable quality of regrind material.

There are many ways to mitigate the creation of burnt PVC or CPVC, but there are no truly safe ways to reprocess degraded PVC or CPVC. Essentially, degraded or burnt PVC/CPVC should be considered waste and thrown away accordingly.

Burnt or Degraded PVC or CPVC on Gelation or Fusion Arc

Purging PVC/CPVC Materials

Definition

By definition, to purge is ‘to get rid of.’ In the case of extrusion, purging ensures that contaminants are removed to prepare for a new, contaminant-free application.

Contaminants include the following:

- Particles, dirt, and dust

- Paper

- Cardboard

- Colorants and additives

- Degraded material and carbon buildup

- Metal flakes from the screw, barrel, and check ring

- Rust from the screw, barrel and die

Safety Concerns

PVC can never be processed in the same extruder that has used Acetal. Likewise, an extruder that was used for Acetal cannot be used for PVC or CPVC. Any combination of Acetal and PVC/CPVC produces a deadly gas and may also cause an explosion.

There is no material or purging procedure that will allow you to safely process these two incompatible plastics in the same extruder. Properly review all recommended procedures and safety precautions before removing the screw. These operations are highly machine-specific — and injury or death can occur if handled improperly.

Personal Protective Equipment that is required during purging includes:

- Face Shield (or Purge Guard)

- Heat Resistant Gloves

- Long Cotton Sleeves

- Long Pants

- Closed-Toed Shoes

When purging, it is imperative to keep clear of the front zone of the extruder and to never reach around or under the die. Never attempt to clear the die or touch purge with your hands. A brass, plastic, or wood tool should always be used to handle purge. Purge can reach 400 °C (750 °F) and can remain dangerously hot for a long period of time.

Here are some additional guidelines to ensure the safety of yourself and your co-workers:

- Be responsible and aware of your surroundings

- Inform others around you of your tasks

- Never rush

- Follow procedures

- Avoid distractions

- Use the appropriate tools

- Ask for assistance if needed

- Always follow Lock-Out/Tag-Out protocol

PVC and CPVC are heat-sensitive materials that can begin degrading in only a few minutes. Some unstable materials (including PVC and CPVC) have the ability to create dangerous gases when they degrade. These gases can create pressures that may cause the barrel to explode if the material is left in the heated barrel for too long.

Corrosion & Oxidation Concerns

The chlorine in PVC & CPVC promotes corrosion on any surface it touches. The chlorine gas that is given off when processed promotes corrosion and oxidation of any metal surface it contacts.

Many processors tend to ‘empty’ the barrel when purging the processing equipment, which should always be avoided especially when processing PVC or CPVC. An ‘empty’ barrel will always have residual polymer left inside on the screw and barrel surfaces. This residual PVC or CPVC will degrade and give off chlorine gas which will corrode the screw and barrel surfaces. Since the barrel is heated and mostly filled with oxygen, rust-causing oxidation will be accelerated on all screw and barrel surfaces.

In all cases, whenever the machinery is to be stopped for a period of time, the barrel should be filled with a heat-stable material, such as a purging compound.

Heat-stable materials will minimize corrosion & oxidation during shutdowns and production stoppages. Hot runner molds should be filled with a heat-stable material to minimize corrosion from degrading PVC or CPVC.

Off-specification (off-spec) extrusion-grade Polyolefins and Polystyrenes are also commonly used for purging PVC & CPVC. Off-spec lots are those that do not meet quality requirements and thus cannot be sold to customers for production use. These lots can often be obtained through your material supplier at a discounted rate.

Large Shot Purging

Large Shot Size purging is defined as using a shot size over 50 percent of the maximum shot size. Large shot purging should not be used with PVC & CPVC, since it only cycles the check ring a few times. Due to the larger injection stroke, this method leaves particulates in the feed zone of the screw.

Small Shot Purging

Small Shot Size purging is defined as using a shot size of approximately 10-20% of the machine’s capacity. Small-shot purging involves making many small shots of purge and is preferred when processing PVC or CPVC because it cycles the check ring multiple times. This option will also clear out the feed zone of the screw when purging.

Dry Purging

Dry purging refers to purging the barrel ‘empty,’ leaving a significant amount of polymer baked onto the screw and barrel surfaces. This baking plastic gives off heated chlorine gas, which is corrosive to the screw and barrel surfaces. When the chlorine gas contacts the metal in the presence of heat & oxygen, the process of oxidation or rusting of the screw and barrel surfaces will be greatly accelerated. Dry purging your barrel will result in faster oxidation and corrosion of the screw and barrel surfaces.

Dry purging with PVC and CPVC will coat barrel and screw surfaces with baked & degraded material. Degraded PVC or CPVC creates a chain reaction that degrades the non-degraded PVC or CPVC it comes in contact with. The only way to stop this chain reaction is to purge all the degraded PVC and CPVC off the screw and barrel surfaces – this process uses a lot of purging compounds and consumes a lot of time. This situation can usually be avoided when using the wet-purging technique.

For these reasons, Dry Purging is not recommended for any polymer.

Wet Purging

Wet Purging refers to always keeping the barrel full of material. During production, the barrel should be full of PVC or CPVC. When a shut-down or process interruption occurs, the barrel should be filled with a more stable polymer, such as extrusion-grade polystyrene or polyolefin purging compound. When production resumes, the barrel contains little to no degraded PVC, which helps the technician get the process up and running quickly.

Keeping the barrel full of material also helps maintain positive conveyance of the material during purging, which reduces the stagnation and degradation of PVC and CPVC.

To conduct an effective wet purge, there should be an easy way to empty and clean the hopper, such as a sliding or swinging hopper. Such a hopper can be moved away from the feed throat to stop the transfer of material into the barrel while exposing the feedthroat. With the feedthroat exposed, the technician can quickly follow the PVC or CPVC with a more stable material to safely fill the barrel and avoid degradation. If the machine is to go back into production soon, the hopper can be slid or swung back into position for a quick purge and restart.

At each purging step, the technician should use a telescoping mirror to view the feedthroat and stop purging when the flights of the screw are exposed. The slide or swing hoppers should also have a method of safely emptying the hopper to recover the unused material into a bucket or container during every shut-down or long-term stoppage.

Melt Processing

The purpose of melt processing is to first melt the source polymer from a pellet, powder, flake, or regrind state. This polymer melt is combined and mixed with any needed additives, reinforcements, fillers, or colorants, inside the barrel. Lastly, the melted polymer is converted to a useful or sellable product such as a sheet, film, profile, tube, or plastic pellets.

PVC & CPVC plasticizers, fillers, additives, and heat stabilizers are not fully mixed before processing. During melt processing these components are combined into a polymer matrix often referred to as a gel. Full gelation (or fusion) refers to the point where the polymer matrix has fully formed or gelled and it has achieved its optimal strength. When high performance is required, the goal of processing is to get the PVC/CPVC to a near full gelation state when the final product is formed. More on this topic is covered in the chapter entitled ‘Time, Temperature, and Shear.’

Melting PVC & CPVC

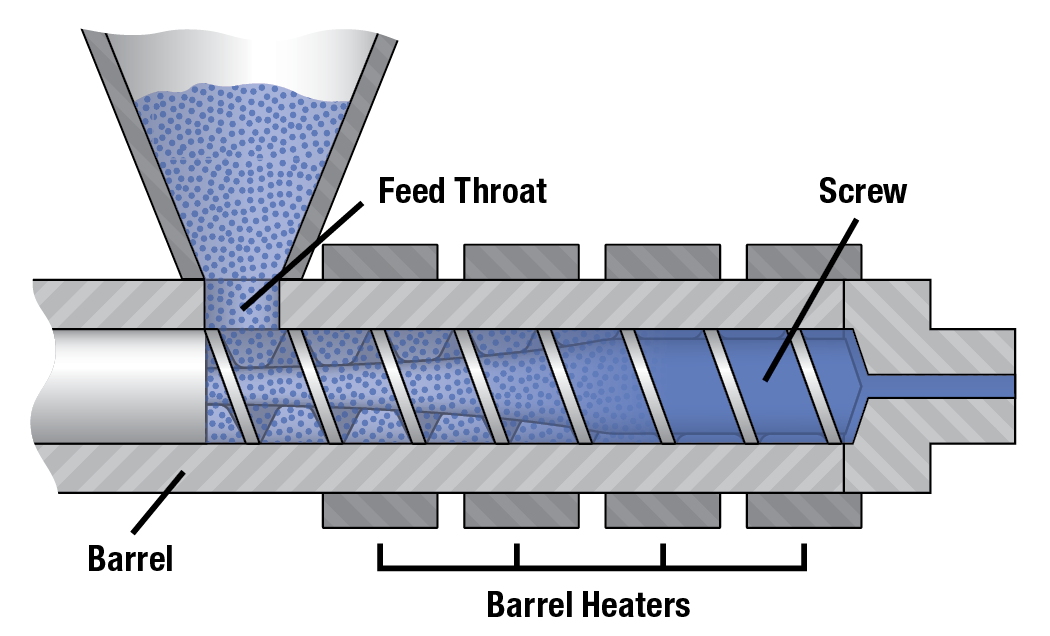

When processing polymers, energy is added to the polymer in the form of heat and shear. Heat is typically provided by heater bands around the barrel. Shear is applied through the use of a screw inside of the barrel which rotates in a process which both works and heats the polymer. The material enters the barrel at the Feed Throat where the screw flights are the deepest as a powder, pellets, and/or regrind.

Screw & Barrel Assembly

If too much heat or shear is used during processing, the polymer can begin to degrade. To help accurately control the temperature of the polymer, most barrels for extrusion are equipped with cooling fans around the heater bands to prevent the polymer from getting too hot.

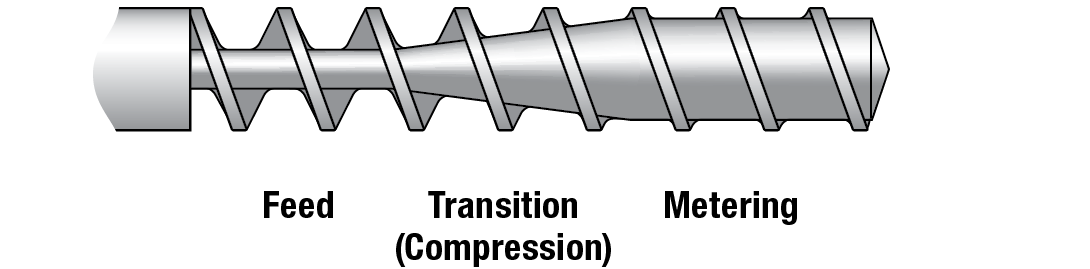

The Feed Zone of the screw has the deepest flights for the best material conveyance. As the polymer is conveyed forward, the flights begin to reduce in depth which compresses the polymer. For amorphous polymers like PS, ABS, PVC, and PC the rear zone tends to be set to a low temperature for optimum conveyance in the feed zone. For PVC and CPVC, a lower temperature rear zone also helps prevent the polymer from getting exposed to too much heat.

The optimum rear zone temperature can be determined using a rear zone temperature study. In such a test, different rear zone temperature can be set and the output measured. The rear zone temperature which provides the highest output is likely the best for that polymer in that machine.

As the polymer is conveyed forward, the flights begin to reduce in depth which compresses the polymer. This polymer compression occurs in the Transition Zone, also known as the Compression Zone.

The compression of the polymer in the Transition Zone puts work and energy into the polymer through a process called Shear. The combination of shear and barrel heat causes the polymer to soften and melt within the barrel. To help prevent excessive shear and heat generation, a screw designed for PVC uses a long gradual transition zone across the entire length of the screw. This design applies shear slowly and gradually to help avoid any excessive shear and degradation.

The Metering Zone at the end of the screw has the shallowest flight depth. This helps pump the melted polymer to the front of the screw as well as provide additional mixing. In the case of PVC and CPVC materials, the material typically requires little to no metering after melting.

To minimize the shear applied PVC & CPVC, the screw will have a transition which consumes most of the overall screw length. In most cases 80 to 100% of the PVC & CPVC screw’s length is the transition zone which is large compared to a General-Purpose screw which typically uses less than 50% of its overall length for the transition zone.

General Purpose Screw Design

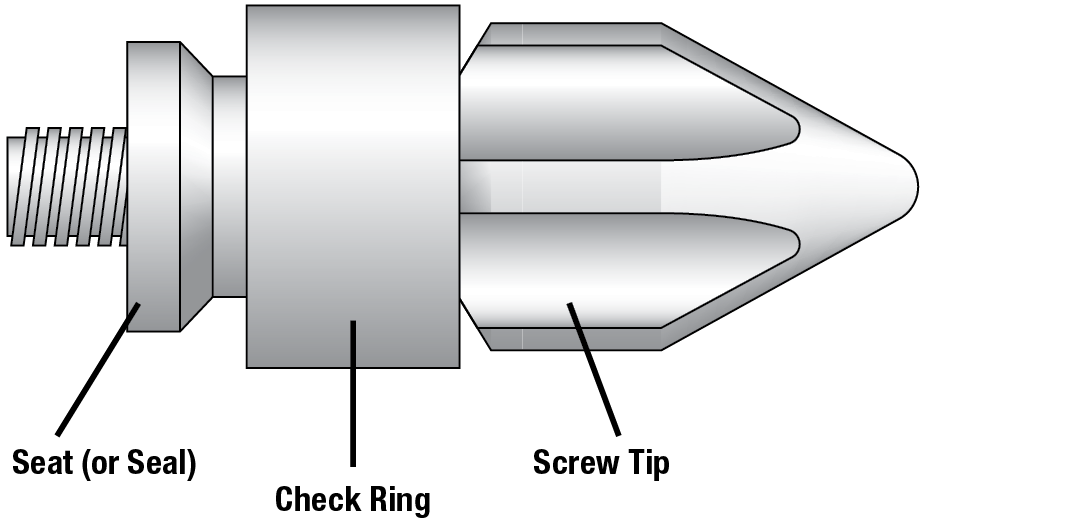

Most plastic injection molding machines use a 3-piece check ring assembly at the tip of the screw. This assembly is acceptable for non-performance PVC/CPVC applications where the polymer is not close to degradation. This screw tip assembly is often preferred for lower viscosity flexible PVC materials which tend process better with a check ring to seal and prevent back flow. The downside to this assembly is that there are multiple surfaces where the PVC may stagnate and begin to degrade. You will likely need to purge the barrel more often when processing PVC or CPVC with a check ring assembly to prevent material degradation.

When melted properly, the polymer at the front of the screw is ready to be processed. During processing, the polymer is forced to flow using pressures up to 1,500 psi (pounds per square inch) or 100 bar for extrusion and blow molding processes or 15,000 psi (pounds per square inch) or 1000 bar for injection molding processes.

Once processed into its final form, the polymer is cooled down enough to maintain its final form and function. During the cooling process, energy is removed from the melted polymer, causing the final product to shrink. In the case of injection molding, the final part will have smaller dimensions than the injection mold. In the case of extrusion, the final product will shrink in the downstream cooling system. The slower the polymer cools, the more shrinkage the polymer encounters.

Some polymers such as PVC are often processed in a vented barrel to release moisture and volatiles from the melted material. The screw used for such extruders have a vent zone which has deep flights similar in depth to the feed zone. The depth of this zone creates a low-pressure zone where the polymer stays in the barrel where volatiles can be vented through a hole in the barrel.

If material moisture is being vented, the barrel will usually vent to atmosphere, but more volatile materials like PVC will often use a filtered vacuum system to actively remove the volatiles from the barrel.

Typical 3-Piece Check Ring Assembly

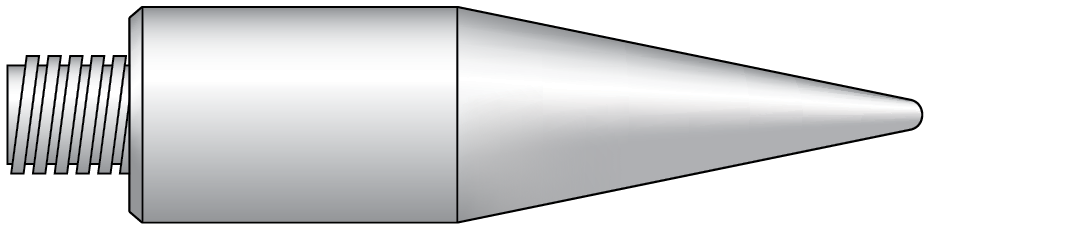

In performance PVC and CPVC molding machines, a smear tip assembly is preferred because the design is streamlined to help prevent material stagnation and degradation. The small clearance between the smear tip and the barrel walls allows the material to flow slowly forward during recovery while minimizing material backflow during injection where the flow rate is significantly faster.

Typical Smear Tip

Viscosity, Shear Rate, and Orientation

Viscosity is a measure of a polymer’s resistance to flow. Shear rate is a function of the material flow rate and the cross-sectional area of flow. Shear rate is increased by either reducing the cross-sectional area or increasing the material flow rate. With polymers, an increase in shear rate causes the polymer chains to align in the direction of flow. This alignment is called orientation. The polymer is stronger in the direction of flow due to polymer chain orientation. Slowing the product cooling with increased material or coolant temperature will reduce this orientation.

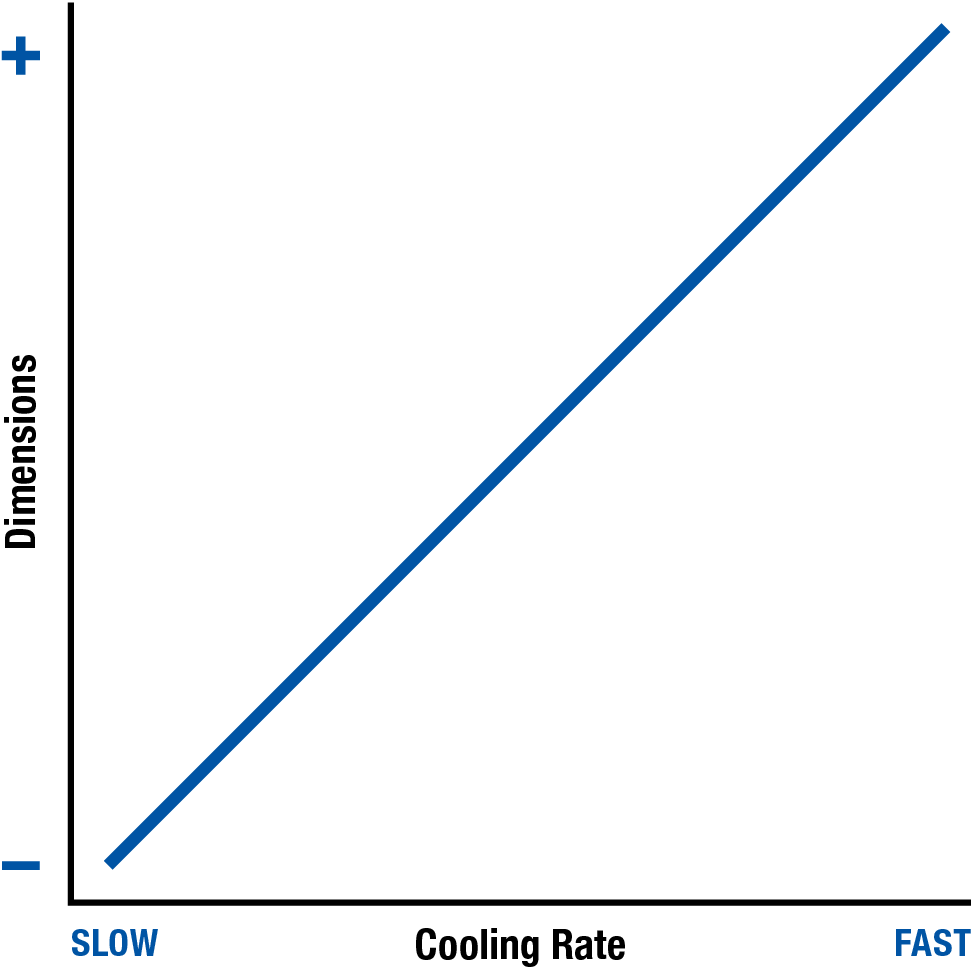

Polymer Cooling Rate

When cooled, polymers will shrink as the molecules reduce their energy level and consume less space, but the amount of shrinkage that occurs depends on the cooling rate. With all polymers, a slower cooling rate allows for more time for polymer chain mobility. This increased chain mobility allows the polymer chains to pull themselves closer together due to a large amount of intermolecular attraction.

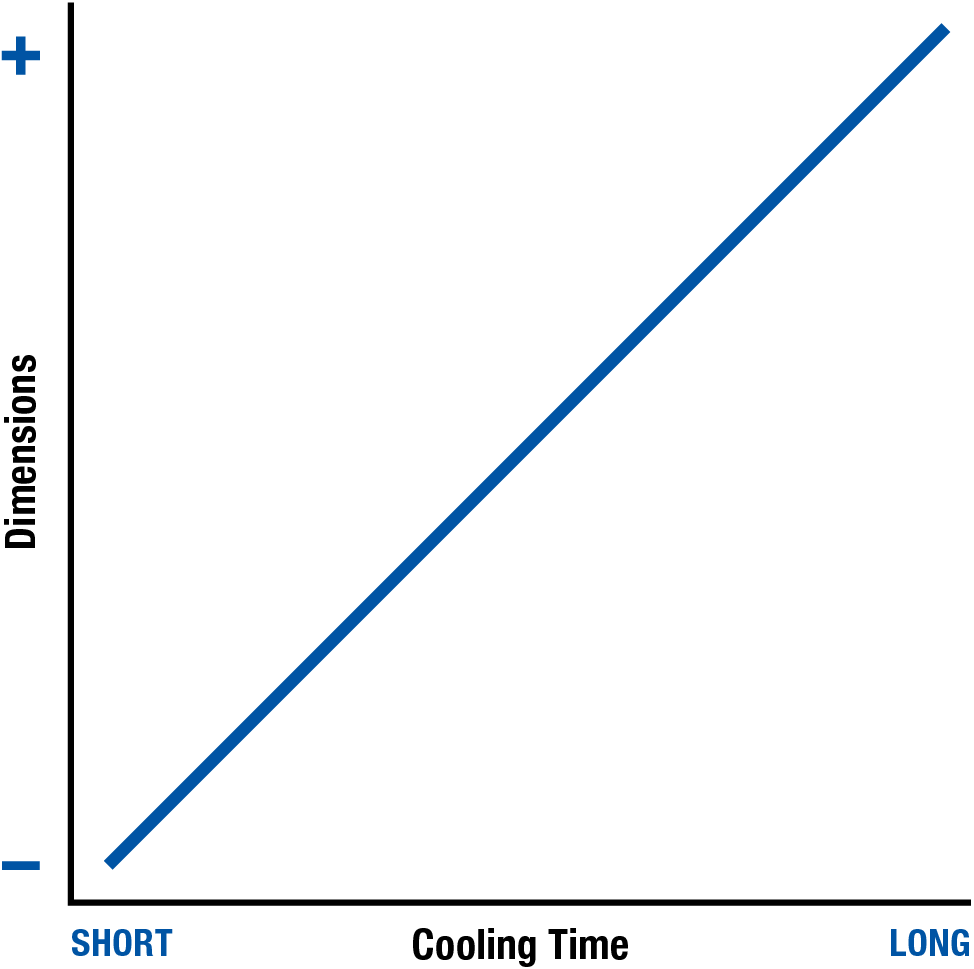

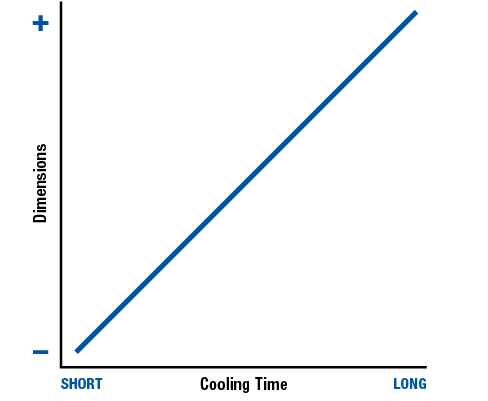

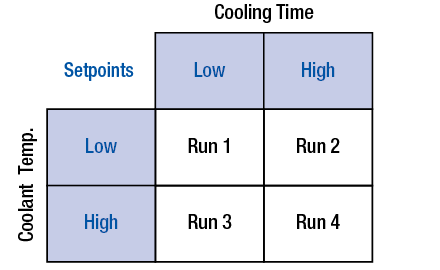

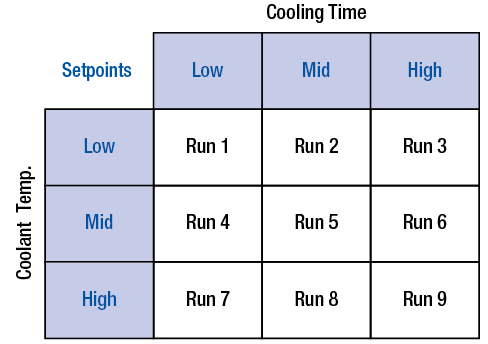

The cooling rate is an important factor in plastic part dimensions. The slower the cooling rate, the more the polymers will have time to shrink due to intermolecular attraction. The graph below provides a basic example of how the polymer dimensions will increase with a faster cooling rate.

Cooling Rate and Part Dimensions

The hot plastic is typically cooled using water as a coolant. For injection molding and blow molding processes, this cooling takes place inside a water-cooled mold. For extrusion processes, this cooling typically takes place inside a water tank or water chilled rollers. Blown Film is one process that uses forced air as the primary method of polymer cooling. The two factors that affect Cooling Rate are temperature and cooling time.

Temperature

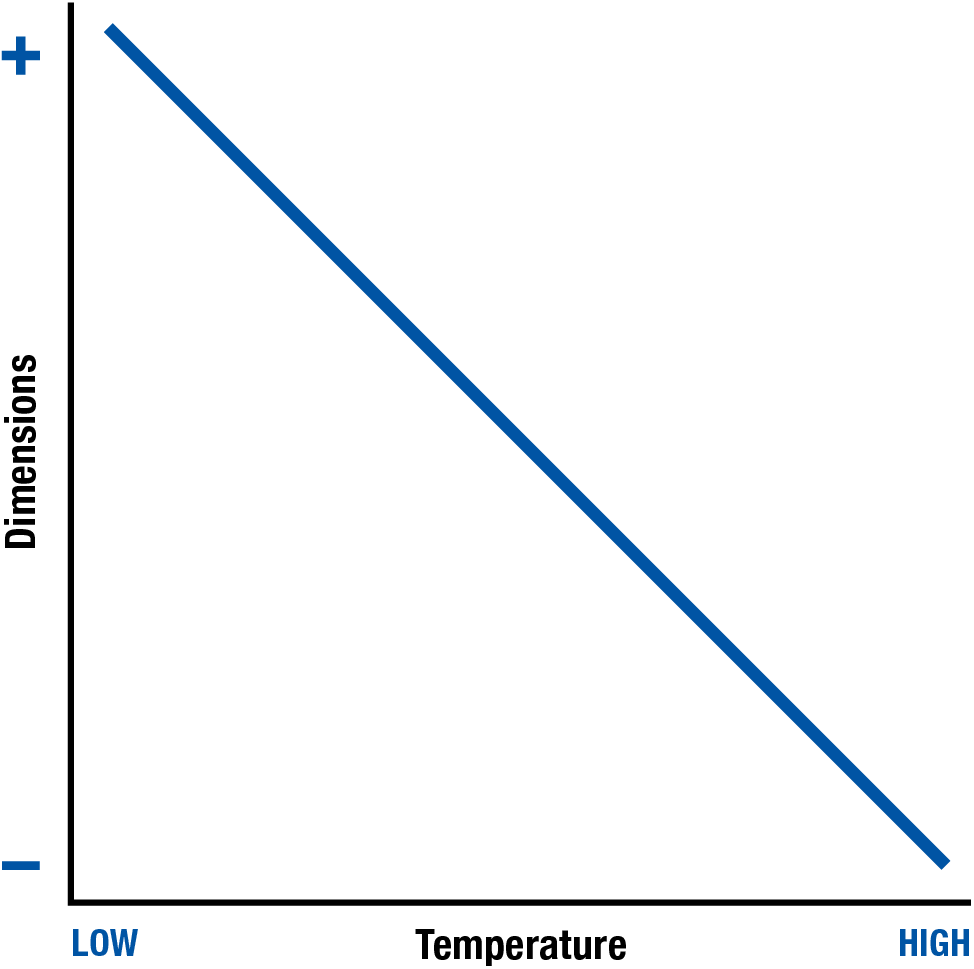

The higher the temperature of the melted plastic or coolant, the slower the cooling rate. The rate is slower because it takes longer for the heat to be removed from the polymer resulting in smaller dimensions. Likewise, lower temperatures cause the heat to be removed faster, resulting in a faster cooling rate. In general, lower temperatures cause larger dimensions and higher temperatures cause smaller dimensions.

Temperature and Part Dimensions

Cooling Time

The time the plastic is being cooled is the cooling time. The cooling time refers to the time when the heat is being removed from the plastic quickly. The longer the Cooling Time, the quicker the heat is being removed from the polymer. For injection molding and blow molding processes, this is the time the mold remains closed after the plastic has been forced against the mold surface. For extrusion processes, cooling time refers to the time the plastic remains in the cooling system, such as the cooling tank or chiller rollers. In extrusion, a faster line speed causes a lower cooling time.

A longer cooling time causes a faster cooling rate which results in larger dimensions. Shorter Cooling Times remove less heat resulting in a slower cooling rate and smaller dimensions. For these reasons, a longer cooling time causes larger part dimensions while a shorter cooling time will result in smaller dimensions.

Cooling Time and Part Dimensions

Basic PVC & CPVC Machinery Concerns

The chlorine present in PVC and CPVC will promote corrosion of any surface it touches. The chlorine gas which is given off when processing chlorine will promote oxidation with any metal surface it contacts.

All metal surfaces should be made of stainless steel whenever possible because of its inherent resistance to corrosion and . Corrosion-resistant coating such as chrome, teflon, rubber, plastic, or a powder-coat (similar to paint, but much more durable) tend to work very well, except they can often be removed when abraded or impacted. In many cases, processors use stainless steel with a corrosion or oxidation resistant coating to maximize the corrosion and oxidation resistance of their metals.

For process machinery, stainless steel is the preferred material for exposed surfaces such as the screw and barrel. For example, a PVC screw may be constructed from chrome and teflon-coated stainless steel with a highly-polished ‘Class A’ finish.

All surfaces where the polymer flows must be streamlined with no places where the polymer can stagnate and begin degrading. The barrel and screw surfaces should be polished to a smooth, mirror-like finish. For injection molding, the inside of the end cap and nozzle must also be polished, ensuring they are perfectly centered and aligned so the internal surfaces are smooth to the nozzle tip. For extruders and blow molders, the inside of the adaptor and die should also be polished, with all components perfectly centered and aligned to ensure smooth internal surfaces to the exit of the die.

Injection molders and blow molders will also use stainless steel molds and tie bars. Extruders will use stainless steel dies, cooling tanks, and downstream equipment. Plastic pipes and hoses with brass fittings are also common to prevent oxidation of the water system.

All exposed surfaces — including the outside of the mold or die — should be cleaned regularly with an acid neutralizer to mitigate the impact of chlorine gas and then sprayed with a surface protectant or lubricated if it is a moving part.

Quality Assurance & Quality Control

The industry trend is to move towards quality assurance (QA). However, the difference between quality control (QC) and quality assurance (QA) with respect to plastics processing, is not always clearly understood. In general, quality assurance involves producing the acceptable product using the same process each and every production run.

Although there is much more behind both quality control and quality assurance practices, this section will cover some basic concepts critical to plastics product quality. The following sections of the guide cover factors important to plastic product quality.

Subjective Quality Standards

According to the Oxford Dictionary, ‘Subjective’ is defined as ”based on or influenced by personal feelings, tastes, or opinions”. Subjective quality involves accepting or rejecting product quality based on the opinion of the person inspecting the product.

Subjective standards are those which might vary from person to person, depending on the experience and knowledge of the person inspecting the product. This typically involves determining whether the product is acceptable or rejected based on the product inspector’s opinion. Examples of subjective quality criteria include visual defects such as sinks, warpage, surface finish, shiny spots, dull areas, and scratches. With good training, experience, and knowledge of the customer’s requirements, a quality inspector can make educated decisions and determinations based on whether the product is good or bad. However, these decisions can still vary from one inspector to another.

Although there will always be the need for quality personnel to make subjective judgment calls in questionable situations, the best practice is to evaluate product to a consistent and objective quality standard each and every production run.

Objective Quality Standards

According to the Oxford Dictionary, ‘Objective’ is defined as “not influenced by personal feelings or opinions in considering and representing facts.” Objective Quality Standards involve accepting or rejecting product quality based on specific quantitative or comparative standards.

Quantitative standards are those which can be measured, such as a specific dimension, product weight, or impact strength. These standards also include quality aspects which can be measured with gauges such as a go/no-go gauge, fit gauge, colorimeter, or gloss meter. Quantitative standards can be made by different people with the expectation that they will come to the same conclusion. For example, if the acceptable dimension is 3.000mm +/- 0.020mm, then anyone encountering a measurement of 3.005mm would agree the dimension is within specification. Advanced quality standards such as Geometric Dimensioning & Tolerancing (GD&T) provide methods for quantifying complex measurements such as surface, flatness, concentricity, and maximum or minimum material conditions. GD&T measurements are typically measured using advanced equipment such as a Coordinate Measuring Machine (CMM), which can take many measurements while using a computer to quantify the measurement objectively.

Objective quality standards apply not only to the product being inspected, but also to the process used to manufacture it. For example, the process itself can have maximum and minimum limits on injection pressure, material temperature, back pressure, weight, mold coolant temperature, dimensions, and cycle time. Some of these limits can be monitored directly by the machine controls, others must be measured with a temperature probe or weighing scale. Plastics processors who provide true quality assurance to their customers have systems in place to ensure that both the product and the process remain consistent from run to run.

Objective quality standards help ensure the technician can produce product the customer will find acceptable — each and every production run.

Quality Control

For plastics processing, quality control involves inspecting product during first piece approval and during production to prevent defects from getting to the customers. There are many quality strategies focusing on how much product is inspected at specific intervals, most of which are designed to balance the risk of bad product getting to the customer with the cost associated with product inspection. In general, the goal of quality control is to create inspection systems to prevent bad or faulty product from reaching the customer. Statistics and proper inspection strategy can significantly improve the effectiveness of your quality control systems. Aside from routine inspection, quality control does not take any steps in preventing bad product except through first piece approval at the start of a production run.

Quality control is always a key aspect to customer retention since it can be devastating when the customer receives bad product, but it is not a substitute for effective quality assurance techniques. In general terms, quality control is focused on preventing bad product from reaching your customer, but not ensuring that there is consistency when a product is manufactured by the production machinery.

Quality Assurance

For plastic processing, quality assurance starts with making acceptable product that conforms to objective quality standards with process which conforms to the approved documented process. In practice, this involves verifying both the product meets objective quality standards and the process conforms with the approved process sheet. This dual product and process approval should take place at first piece approval, at pre-determined time intervals, and after any significant change is made to the process. Significant changes include a material lot change, adjustment to regrind percentage, color change, machinery repair, or equipment change.

If acceptable products are being produced with an approved process during every production run, then quality has a high level of confidence that the customer is receiving quality products over time. This is the foundation of Quality Assurance for plastics processors. With most plastics, following the entire process sheet for every production run helps maintain strong process consistency.

Quality Assurance for PVC & CPVC

With respect to PVC and CPVC, the process-specific documentation portion of the process sheet should be duplicated each and every time. On every production run, the product should have the same cooling time, short shot weight, packing pressure, etc., as these parameters do not have a significant effect on gelation or fusion of performance PVC/CPVC. In this case, quality assurance involves making sure these remain the same every time the process runs, regardless of the shift personnel.

With PVC and CPVC, the run-specific documentation portion of the process sheet should be duplicated whenever the source materials are similar. When the source material is different, these may be adjusted to achieve the proper time, temperature, and shear balance complication to reach the amount of gelation or fusion required to meet end-use requirements

For performance PVC/CPVC, you may need to reduce the material temperature or back pressure to compensate for a material lot that degrades easily or was dried twice. Conversely, you may have a part that is visually acceptable but is failing performance testing. A rise in material temperature or back pressure could be helpful in increasing the amount of gelation or fusion in your final performance PVC/CPVC product.

The more documented history you have from your material suppliers, the more likely you will be able to compensate for these changes. When possible, work with your PVC/CPVC supplier to obtain more consistent source material over time.

Scientific Documentation

Documentation Concerns

With performance PVC & CPVC, all components are not fully mixed before processing. During processing, these components are further combined into a polymer matrix, which is often referred to as a gel. The combination of these components is referred to as gelation or fusion. Full gelation is the point where the polymer matrix or gel has fully formed, and the polymer achieved its optimal strength and resistance properties. Performance PVC & CPVC applications are those which need a high percentage of gelation in the final part to meet end-use requirements.

The amount of time, temperature, or shear required to reach full gelation of your PVC or CPVC will vary depending on many factors. A change in material supplier, material blending equipment, or pelletizing equipment will vary the time, temperature, and shear history of your source material. A change in processing equipment, auxiliary equipment, or drying equipment will change the time, temperature, or shear history of the polymer. These differences in source material may require process changes to ensure the final part meets end-use requirements. For more on the above, please review the ‘Time, Temperature, and Shear’ chapter of this reference guide.

The more material and process information you can document for each production run, the better you can identify these changes when they occur. With the right information, you should be able to accommodate source material changes with your process.

In this chapter, we will review the 3 primary forms of documentation, as well as process calculators used for documentation:

- Setup Sheet

Document process inputs - Process Sheet

Document process outputs (standard and run-specific) - Process Change Log

Document all process changes

Process Inputs vs. Process Outputs

Process inputs are the machine-dependent parameters entered into the processing equipment. These settings include parameters such as: injection speeds, barrel temperatures, and transfer position.

Process outputs are machine-independent, process-specific parameters, which result from the process. These outputs include: temperatures, pressures, weights, times, as well as any additional information important to the product or process. Additional information which are also considered process outputs include: part measurements, material dewpoint, quality information, clamp tonnage, photographs, and observations.

Open Loop vs. Closed Loop Process Controls